The Architect's Drawing Board

Technical Bulletin

New ANSI requirements for grade 2 braille.

The ADAAG Review Federal Advisory Committee's FINAL REPORT "Recommendations for a New ADAAG", is expected to be adopted by the ADA Law in early 2000.

In this report the Committee addresses new grade 2 braille requirements for signs.

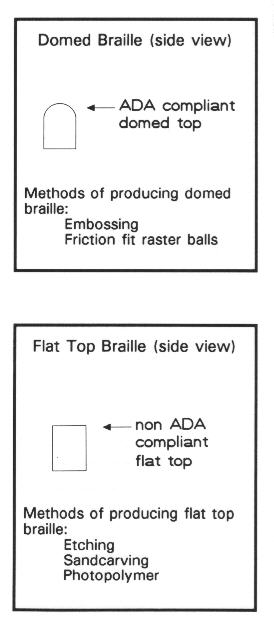

The Committee's final recommendation requires all signs containing grade 2 braille, as mandated by the ADA, to now have braille with domed or rounded tops. Flat tops on braille will no longer be ADA compliant. Additionally, the Committee has established dimensions for braille dots.

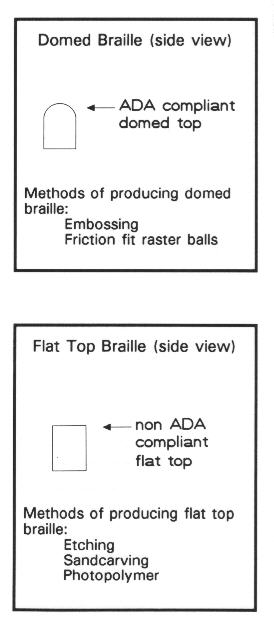

Most methods of producing grade 2 braille currently utilize technology that produces braille with flat tops and sharp edges. "Flat top" braille will no longer be compliant when the Committee's recommendations are adopted as part of the ADA Law.

Braille with rounded or domed tops have been found to be considerably easier to read by the vision impaired population, due to its shape and feel.

Two current methods of producing rounded or domed grade 2 braille that meet the Committee's recommendations are embossing and raster balls. Of these two methods only embossed grade 2 braille is an integral part of the sign.

Embossed grade 2 braille is produced by computer driven machinery that guarantees precise dimensions on each and every braille sign. The braille is embossed directly into the sign face and is not glued or pasted on as a secondary application. The embossed braille can be back filled with hardening compounds to produce solid braille dots.

Raster balls are placed into pre-drilled holes and held in place by friction fitting or gluing the raster ball into the pre-drilled holes. If the raster balls are friction fit into the sign, they are held in place only by the tolerance of the pre-drilled hole. Expansion and contraction of the sign due to environmental changes might cause the raster balls to fall from the sign. If the raster balls are glued into the sign, the possibility exists for excess glue to mar the face of the sign.

In their current state, the braille produced by many of the commonly used braille production methods will no longer be compliant when the Committee's recommendations are adopted as part of the ADA, if their braille continues to have "flat tops" and sharp edges. Theses processes include: Etching, Sand Carving and Photopolymer.

To ensure that you receive grade 2 braille that meets current and proposed ADA requirements and is an integral part of the sign, make sure to specify "Braille to be produced by embossing." on all your ADA sign specification.

The above information was taken from the ADAAG Review Federal Advisory Committee FINAL REPORT "Recommendations for a new ADAAG" and actual experiences with the above mentioned braille production processes.

The Architect's Drawing Board Main Menu

How to contact MEMCO

Send us email at info@memco.net

Send us email at info@memco.net

MEMCO Merrimack Engraving & Marking Co

Methuen, MA

(978) 683-5335

Send us email at info@memco.net

Send us email at info@memco.net

Send us email at info@memco.net

Send us email at info@memco.net